Feature

This equipment is widely used in research institutes, universities and private companies as research development of ceramics green sheet. And recently, it is also used for coating of paints, chemicals, adhesives, plastics, composite materials, thin films, etc.

Easy to handle and clean. Able to measure from a simple desktop type to experimental equipment of a closed drying zone with a length of several meters.

Roller pressure feeding method of film, unwinding / winding method can be selected and drying hot wind zone can be set for voluntary length as an option.

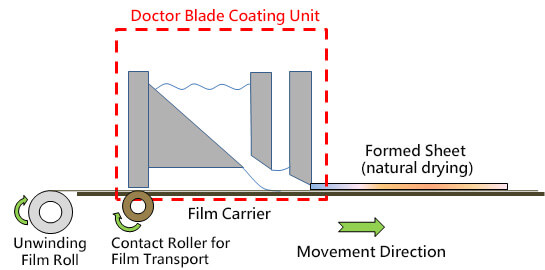

Principle

The slurry in the dam flows out of the adjustable clearance with the parallel blade and a green sheet is molded on the moving film.

Specification

Basic Specification

| Type | DP-150 | DP-300 |

|---|---|---|

| Green sheet measurement | Thickness 30um~1.5mm、Width 150mm、 Length 800mm |

Thickness 30um-1.5mm, Width 300mm、 Length 800mm |

| Film to mold sheet | Thickness 100um、width 200mm | Thickness 100um、width 350mm |

| Film conveyance method | Contact type film conveyance roller mechanism | Contact type film conveyance roller mechanism |

| Coating method | Doctor blade method | Doctor blade method |

| Film moving speed | 0.1-0.8m/min(Continuously variable) | 0.1-0.8m/min(Continuously variable) |

| Power supply | AC 1 phase 100V, 25W | AC 1 phase 100V, 25W |

| Outer dimension mm | 1400mmL x 260mmW | 1400mmL x 420mmW |

Customized specification

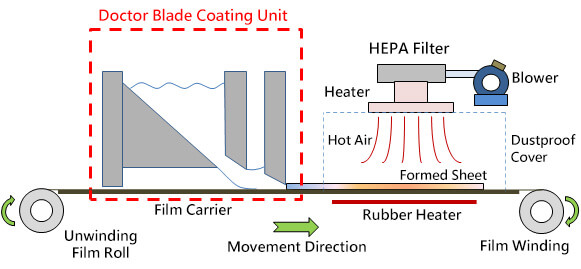

Example of closed・clean drying zone +film unwinding/winding specification(DRPTC-150)

Structure principle chart of DRPTC-150

The slurry in the dam flows out of the adjustable clearance with the parallel blade and a green sheet is molded on the moving film with unwinding mechanism. Fan from blower is filtered by HEPA filter, becomes hot wind with heater and dries green sheet with heating of rubber sheet under conveyor.

Customized specification example

| Type | DRPTC-150 |

|---|---|

| Green sheet measurement | Thickness 30um-1.5mm, Width 150mm |

| Film to mold sheet | Thickness 100um, Width 199mm |

| Film conveyance method | Roll to Roll |

| Coating method | Doctor blade method |

| Film moving speed | 0.1-0.8m/min(Continuously variable) |

| Film paper tube shaft diameter | Inner diameter 3 inch |

| Drying zone | Length 2m with casing |

| Drying method (conveyance rail) | Silicon rubber heater。Able to control temperature |

| Drying method (in casing) | Hot wind generator with HEPA filter. Able to control temperature |

| Power supply | AC 3phase 200V, 10kVA |

| Compressed air | 0.5MPa |

| Outer dimension mm | 3550L x 1000W x 1050H |

- Blade part and winding device are separated and intermediate base can be set to voluntary length to make the green sheet long. Film winding type doctor blade equipment can be produced.

- Drying hot wind option: Drying zone is available or not. Open drying, closed drying or clean hot wind (HEPA filter) can be added in case drying zone is available.