Feature

Able to measure from simple shape to complicated shape

Able to measure from simple shape to complicated shape- Pressurizing ability 3-50 tons

- Equipment with high reliability due to many years of experience

Principle

This equipment is an automatic CNC servo press machine specialized in powder processing.

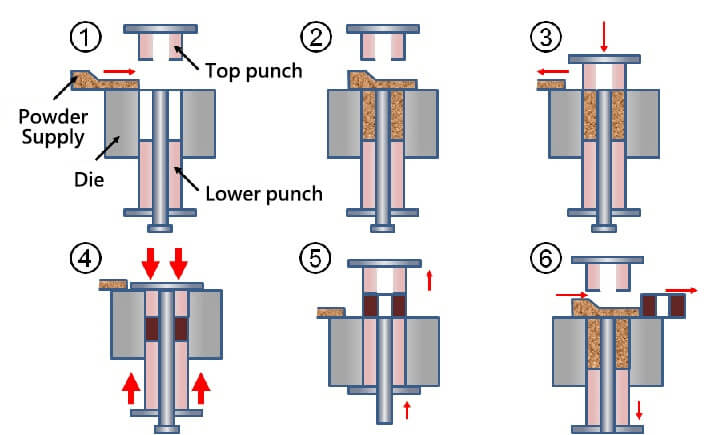

①Consists of die set(die , upper/lower punch) and powder feeder.

②Powder filling: material powder is filled in cave of die by powder feeder.

③Upper punch stand-by: upper punch descends after filling up to the die surface position.

④Pressurization: mold with pressure.

⑤Extraction: product can be extracted after upper/lower punch ascends.

⑥Discharge: next powder filling step starts after product is pushed out.

Purpose

Press molding of ceramics materials etc.

Specification example

| Type | APC-20SSA | APC-20SA |

|---|---|---|

| Maximum press force | 20,000kgf | 20,000kgf |

| Maximum extrusion force | 7,000kgf | 7,000kgf |

| Maximum filling depth | 100mm | 130mm |

| Maximum lower pressure stroke | 70mm | 90mm |

| Maximum extrusion stroke | 100mm | 130mm |

| Bottom ram control speed | 6 steps control per 10% from 50% to 100% of upper ram speed | |

| Bottom ram stroke | 150mm | 180mm |

| Upper punch hold down stroke | 70mm | 75mm |

| After pressing volume | 0~20mm | 0~20mm |

| Under fill or over fill volume | 0~10mm | 0~10mm |

| Upper punch pressure position adjustment volume | 60mm | 65mm |

| Die surface position adjustment volume | 20mm | 20mm |

| Bottom ram stopper capacity | 7,000kgf | 7,000kgf |

| Molding speed | 6~40SPM | 6~30SPM |

| Filling volume automatic control system | Filling depth control by applied pressure monitoring | |

| Upper ram drive electric type | 7.5Kw AC Servo motor |

7.5Kw AC Servo motor |

| Bottom ram drive electric type | 7.5Kw AC Servo motor |

11Kw AC Servo Motor |

| Press shut height | 500mm | 550mm |

| Machine weight | About 3,200kg | About 3,600kg |