Feature

- Suitable for small beads: It corresponds to 0.015-0.2 mm microbeads.

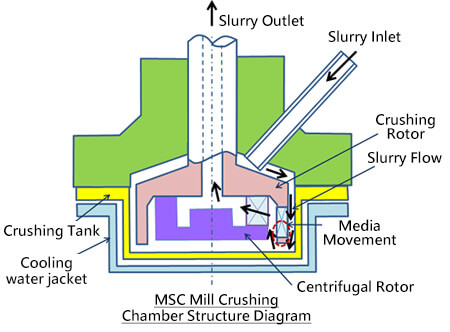

- Original structure: with unique grinding chamber structure, microbeads can be used in a more stable way.

- Excellent grinding/dispersing interaction: By adopting a small tank of L / D (tank length/tank diameter) and a cylindrical rotor, it is possible to give uniform and effective grinding and dispersing power to microbeads.

- Simple structure: Easy to disassemble and clean with simple structure. Maintenance can be made in any direction so that grinding chamber can be swung.

Principle

MSC mill is a circulation operation type. The raw material slurry is charged into tank and sent to MSC mill grinding chamber by its own weight or pump. The product grinded and dispersed by rotary grinding rotor is separated from beads by a rotating centrifugal rotor.

Purpose

Fine grinding of electronic materials, magnetic materials, ceramics raw materials, cosmetics, pharmaceuticals, foods, toners, inks, titanium oxide, barium titanate, various metal oxides, various metals, glass and so on.

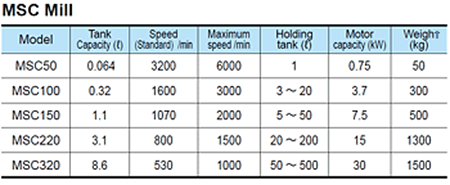

Specification example

|

Medium-large size Medium-large size |

Explainer video:https://youtu.be/_z5Jai_5JA4