Feature

- Various processing to advanced particle design is made possible with the process of the equipment from simple mixing・dispersion to complexing, surface modification and coating etc.

- Forming complex particles while incorporating other particles on the surface of particles and realizing high efficiency complexing, coding and sphericalization.

- Exellent workability with a very simple structure, easy maintenance such as cleaning etc. Easy scale up (Upsizing).

Principle

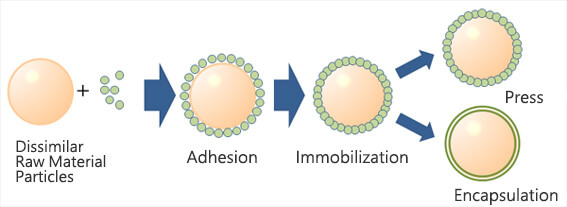

COMPOSI equipment has a special impeller which rotates at high speed inside the tank and has a fixed collision plate.The processed object (powder) put into tank will flow because of the rotation of special impeller and will convect up and down.

Mixing and dispersion proceeds and surface of powder particles is also activated by adding strong shearing action to compacted materials near special impeller (mechanochemical effect).At the same time, on a micro-level, rotation of each particle occurs between tank wall and special impeller. Through granulation by rolling action, compound particles are formed while particles are incorporated onto surface of other particles. Highly efficient composing, coating and conglobation are achieved.

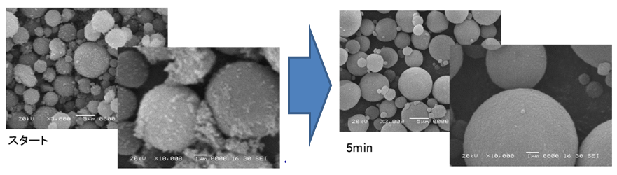

Process example 1:Combining PMMA particles and titanium dioxide particles

(Raw material is a premix of PMMA particles and titanium dioxide particles)

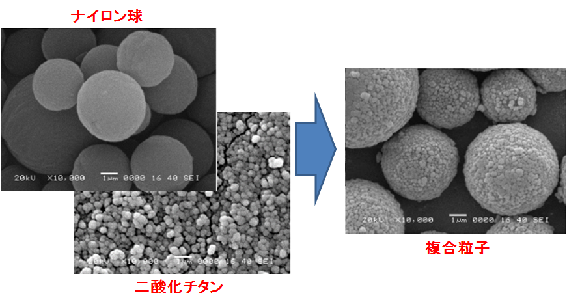

Process example 2:Combining nylon particles and titanium dioxide particles

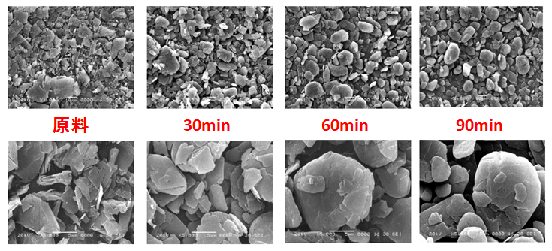

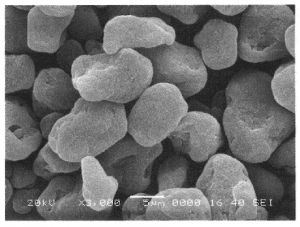

Process example 3:Spheroidization of Graphite (Battery Negative Electrode Material)

Mechanochemical reaction is caused by adding mechanical energy and making squamous graphite spherical in shape by tumbling granulation.

Rolling granulation has the effect of suppressing generation of fine powder to sphericalize with incorporated fine powder.

Process example4:Color toner external addition processing (External addition + Spheroidization)

Coating surface of the toner with external addition such as silica or titanium dioxide to improve peculiarities such as fluidity of toner produced by pulverization method or polymerization method.

Mixer is generally widely used for toner external addition processing, and can be coated for external addition but it is hard to adhere strongly in short time by using the equipment.。

Purpose

Secondary battery materials, electronic materials, magnetic materials, cosmetics, pharmaceuticals, foods, toners, ceramics, catalysts.

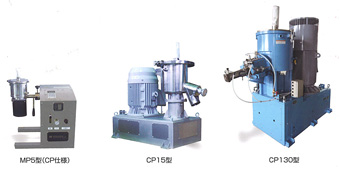

Specification example

| Item/ Type | Total capacity | Motor | Dimension LxWxH | Product weight |

|---|---|---|---|---|

| L | kW | mm | kg | |

| MP5 | 1.6 | 2.2 | 615x450x815 | 60 |

| CP10 | 16.0 | 15 | 1200x640x1100 | 400 |

| CP60 | 63.0 | 75 | 2000x840x1700 | 800 |

| CP130 | 130.0 | 150 | 2300x1000x2200 | 2700 |

| CP230 | 230.0 | 315 | 3000x1200x2500 | 5000 |