Injection molding is a molding method in which plastic and fluid clay is pumped to the tip mold while degassing from the clay using a screw or plunger method and extruded in the same shape.

Features

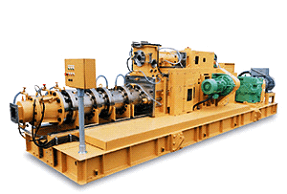

【Type FM】

Rollers in the vacuum chamber, and the upper and lower cylinders and the lower stage. The screw has a water-cooled jacket structure, which suppresses heat generation during high-pressure injection.

【Type MV】

FM type with the roller changed to side-screw type.

Working Principle

参考図面

The material input from the hopper is plasticized and kneaded by the rotation of the screw and injected from the injection port (die) to form a product.

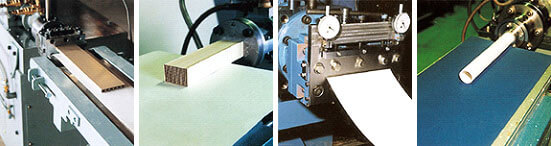

Sheets, tubes, pipes, round bar products, etc. can be made by passing dies of various shapes and structures through this injection port.

Injection dies (dies) need to be designed for each application. Reference below: The shape differs depending on each application.

We will design and provide suitable dies after listening to each customer requirement.

Image

Application

Fine ceramics molding, material building

Specification

| Type | Drive Motor(kw) | Gear Ratio | Vacuum Pump (ℓ/min) |

Approx. body dimensions (WxLxH mm) |

Weight (kg) |

|

|---|---|---|---|---|---|---|

| Upper Motor | Wedge Motor /Lower Motor |

|||||

| FM-300 | 37 | 送料辊 22 下段马达 90 |

10:1 | 550ℓ/min 2.2kw | 22,00×8,200×2,400 | 25,000 |

| FM-200 | 7.5~15 | 下段马达 37~55 | 10:1 | 350ℓ/min 0,75kw | 2,120×6,500×2,500 | 18,500 |

| FM-150 | 5.5~7.5 | 22~37 | 10:1 | 350ℓ/min 0.75kw | 1,100×4,000×2,140 | 5,800 |

| FM-100 | 2.2 | 7.5~11 | 10:1 | 150ℓ/min 0.4kw | 880×2,650×1,650 | 2,000 |

| FM-70 | 1.5~2.2 | 3.7~5.5 | 10:1 | 60ℓ/min 0.2kw | 850×2,500×1,760 | 1,650 |

| FM-50 | 1.5 | 2.2~3.7 | 10:1 | 60ℓ/min 0.2kw | 750×2,100×1,600 | 1,500 |

| FM-40 | 1.5 | 1.5~2.2 | 10:1 | 25ℓ/min 0.2kw | 720×1,600×1,320 | 700 |

| FM-30 | 0.4 | 0.4~0.75 | 10:1 | 25ℓ/min 0.2kw | 600×1,050×1,150 | 400 |

| FM-20 | 0.4 | 0.4 | 10:1 | 25ℓ/min 0.2kw | 370x740x1,100 | 200 |

| MV-450 | 110 | 200 | 10:1 | 6,000ℓ/min 15kw | 2,200×9,900×2,900 | 34,000 |

| MV-310 | 22~37 | 45~75 | 10:1 | 550ℓ/min 2.2kw | 1,950×6,700×2,100 | 12,500 |

| MV-250 | 15 | 37 | 10:1 | 550ℓ/min 2.2kw | 1,800×4,800×1,800 | 6,000 |

| MV-200 | 15 | 22 | 10:1 | 350ℓ/min 0.75kw | 1,500×4,000×1,500 | 5,000 |

We also handle related equipment such as laboratory machines for researches, raw material kneaders used in the pre- and post-processes, and high-speed mixers.

Please feel free to contact us.