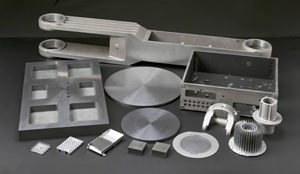

Engineering ceramics products with high quality features such as wear resistance, corrosion resistance, heat resistance etc.

- Silicon carbide(SiC)

Purpose: Sliding parts, grinding machine parts, semiconductor manufacturing equipment parts, molding machine parts etc. - Silicon nitride(Si3N4)

Purpose: Molding parts, casting parts, die-casting machine parts, welding machine parts etc.

Ceramics & Metal composite parts(MMC)

Composite material of metal and ceramics reduces weight with rigidity by combining base metal with ceramics reinforcing material. Furthermore, material property like heat dissipation etc. can meet customer’s requirements.

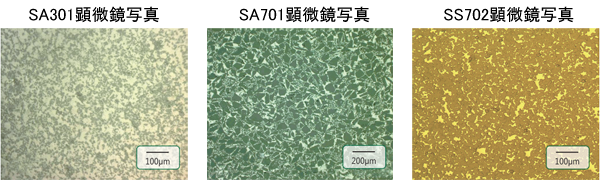

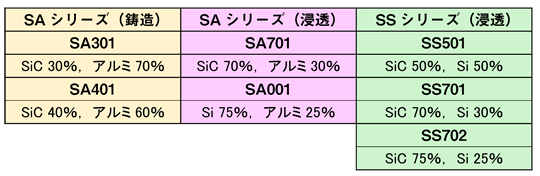

SA301 SA401

|

SA701

|

|

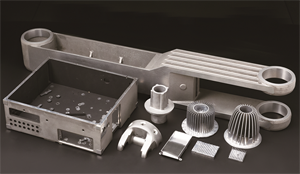

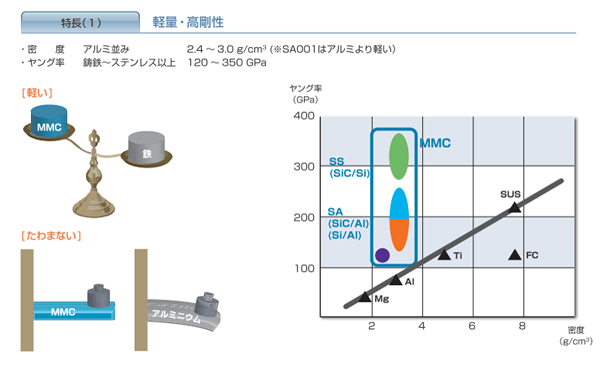

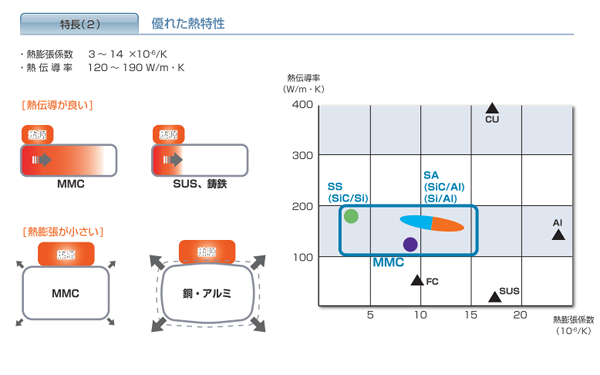

SA301、SA401 are composite materials containing SiC ceramics particles for 30 or 40 vol% in aluminum alloy. We manufacture with casting method of sand casting, die casting. Equivalent with weight of aluminum and equipped with more than cast iron for young’s modulus and able to measure mass production small products, big products and complicated shapes.。 Merit:Light weight, high rigidity, high thermal conductivity, low thermal expansion, vibration attenuating, large・complex shape can be made. Purpose: Liquid crystal manufacturing equipment・inspection equipment, machine tool, robot, semiconductor manufacturing equipment・ inspection equipment, mounter, bonder, various heat slinger.

|

SA701 is a composite material which infuses aluminum in SiC porous material(70vol%). Equivalent with weight of aluminum and equipped with young’s modulus 1.3 times stronger than stainless and excellent for heat characteristics.Easier to upsize than ceramics and fracture toughness goes up by impregnating metals and realizes the strength for cracks. Merit: Light weight, high rigidity, high thermal conductivity, low thermal expansion, vibration attenuating, larger size for ceramics, fracture toughness UP for ceramics.。 Merit: Light weight, high rigidity, high thermal conductivity, low thermal expansion, vibration attenuating, larger size for ceramics, fracture toughness UP for ceramics. Purpose: Liquid crystal manufacturing equipment・inspection equipment, semiconductor manufacturing equipment・ inspection equipment, mounter, bonder, |

SA301 SA401

|

SA701

|

| SS501, SS701, SS702 are composite materials which infuses metal silicone in SiC porous material(50-75vol%).

We realized physical properties matching needs by changing SiC ratio. Suitable for manufacturing equipment of semiconductor・liquid crystal and inspection equipment without failure on the surface. Merit:Light weight, high rigidity, high thermal conductivity, low thermal expansion. Purpose:Liquid crystal manufacturing equipment・inspection equipment, semiconductor manufacturing equipment・ inspection equipment, optical system parts, various heat slinger |

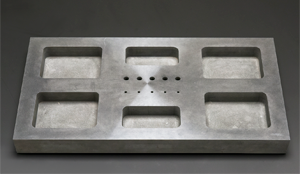

SA001 is a composite material which infuses aluminum in SiC porous material(75vol%). Lighter than aluminum material, equipped with high rigidity as cast iron and low thermal expansion close to ceramics material are made. Merit: Light weight, high rigidity, low thermal expansion Purpose:Electrostatic chuck pedestal, probe card part

|

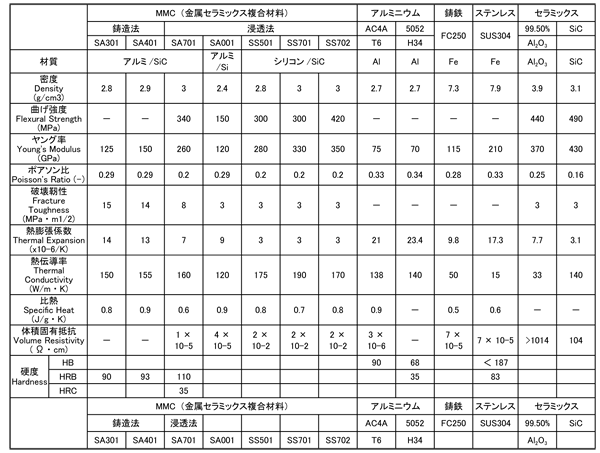

MMC特性表