For sintering process in fine ceramics and other fields, electric furnace is recommended and provided for process such as normal pressure sintering, pressure sintering, reaction sintering, atmosphere sintering, vacuum sintering and ultra-high temperature etc. that is suitable for various materials, purpose and designated specification.

Purpose

- Sintering of oxides, non-oxide ceramics

- Sintering of carbon, graphitization

- Atmosphere sintering in special raw materials such as phosphor etc.

Specification example

Four-sided heater carbon furnace

- Maximum temperature:1700℃

- Atmosphere pressure:1×10^4Pa-0.14kgf/cm^2

- Atmosphere: Vacuum, N2, Ar, He, H2

| Heat zone size | 600W x 600H x 1400D(mm) |

|---|---|

| Temperature control | Programmable PID Temperature Controller (Up/Down 2 zone) |

| Temperature measurement | C type Thermocouple |

| Heater | Graphite |

| Thermal insulation | Graphite |

| Chamber | SUS304 water cooling chamber(Circular chamber) |

| Recorder | Digital recorder |

| Cooling water | 250 liter/min |

| Power supply | AC220~440V, 3P, 230KVA |

| Vacuum ultimate pressure | Max 1.0×10-5 torr |

| Vacuum pump | Rotary pump (3500 liter/min) & 20″ Diffusion pump |

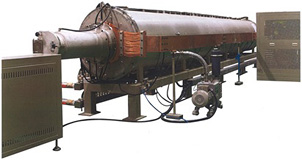

Graphitization electric furnace

- Temperature range:1500~2800℃

- Atmosphere:Ar

| Heat zone size | ID 240 x 7437L(mm) |

|---|---|

| Temperature control | Programmable PID Temperature Controller (1 zone) |

| Temperature measurement | Pyrometer(900~ 3500℃) |

| Heater | Graphite, Tube type(Ten zone) |

| Thermal insulation | Graphite |

| Chamber | SUS304 water cooling chamber(Circular chamber) |

| Recorder | Digital recorder |

| Cooling water | 600 liter/min |

| Power supply for operation | AC380V, 3P, 33KVA |

| Power supply | AC380V, 3P, 608KVA |

| Vacuum ultimate pressure | Max 5.0×10-0 torr |

| Vacuum exhaust | Rotary pump (3500 liter/min) |

| Gas flow volume | 400 liter/min (Flowmeter 50 liter/min x 8ea) |

Stacking type heater carbon furnace

- Maximum temperature:1400℃

- Atmosphere:N2, H2(vacuum)

| Heat zone size | 900W x 900D x 650H(mm) |

|---|---|

| Temperature control | Programmable PID Temperature Controller (Up/Down 2 zone) |

| Temperature measurement | B type Thermocouple |

| Heater | Graphite |

| Thermal insulation | Graphite |

| Chamber | SUS304 water cooling chamber(Square chamber) |

| Recorder | Digital recorder |

| Cooling water | 250 liter/min |

| Power supply for operation | AC220~440V, 3P, 230KVA |

| Vacuum ultimate pressure | Max 1.0×10-2 torr |

| Vacuum exhaust | Dry pump (7000liter/min) |

| Option 1 | Automatic door opening system opened by air cylinder |

| Option 2 | Quick cooling heat exchanger |

| Option 3 | Chamber full cover |