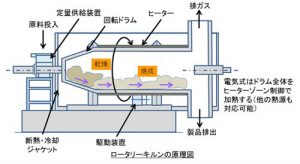

Principle

Rotary kiln to sinter mass volume samples for production.

Continuous projection of samples can be made by quantitative supply device and auto feeder.

Sintering unevenness of sample can be reduced by rotating drum with driving device and independently controlling heating zone of electric furnace part, and measuring to customer’s original heat curve can also be made. Continuous operation can be made, because products after sintering are discharged out of outlet.

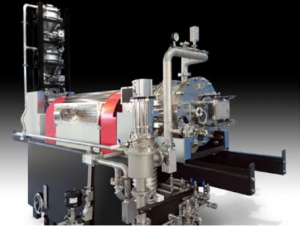

●High temperature rotary kiln

Feature

- High temperature processing which can’t be done by metal can be made by usage of retort such as quartz, special metal, etc.

- Stable atmosphere control can be made by original airtight structure.

- Uniform and short time heating can be made by rotation stirring.

- Nitrogen, hydrogen, oxygen, argon and various atmosphere gas can be used

Purpose

Various powder materials, metal materials and others

Specification example

| Kiln type | Out heating type rotary kiln |

|---|---|

| Heating temperature | Max. 1200℃ |

| Processing atmosphere | Nitrogen, hydrogen, oxygen, others |

| Retort external dimension | ø250x950mm(Heating parts) |

| Retort material | Transparent quartz, SUS 310 S, Inconel, special metal |

| Retort rotation speed | 1~15.0rpm |

| Heating source | Resistance heating element (metal) |

| Heating ability | 25kW |

●Special atmosphere kiln+Vacuum rotary kiln

Feature

- High temperature processing can be made by usage of peculiar metal retort.

- Vacuum heat processing can be made by original airtight structure.

- Uniform and short time heating can be made by rotation stirring.

- Various atmosphere gas can be used. High purity atmosphere can be made in short time with combination of vacuum pump.

Purpose

Various powder materials, metal materials and others

Specification example

| Kiln type | Out heating type rotary kiln |

|---|---|

| Heating temperature | Max. 1050℃ |

| Ultimate vacuum | Less than 1Pa |

| Processing atmosphere | Nitrogen, hydrogen, vacuum, others |

| Retort external dimension | ø250x950mm(Heating parts) |

| Retort material | Special metal |

| Retort rotation speed | 0.4~4.0rpm |

| Heating source | Resistance heating element (metal) |

| Heating ability | 20kW |