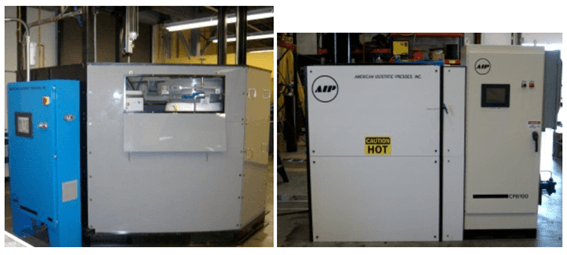

AIP designs and builds Warm Isostatic Presses for many applications. These systems can be gas or liquid pressurized and are often used for plastics and laminated products. WIPs are usually purpose built and can be low pressure all the way to extreme pressures. Liquid WIP systems range to 250 C and gas WIP systems can go to 500 C. Both cold and hot wall versions can be supplied. AIP has worked with many companies to also develop the molding and technologies required to make the process cost effective and possible. AIP has toll WIP capabilities and can offer testing to interested parties.

Feature

WIP unit is designed for other applications requiring artificial pressure.

Custom mode is needed when special functions are required.

WIP system for production uses water or oil thermal fluid and heated using external circulation heater.

Touch screen with computer-based graphical operation

Interface is standard.

Benefits compared to general press machine

- Excellent in temperature uniformity performance

- Can be processed in dry state.

- Strength and accuracy are excellent.

- High densification, low density variation and uniformity

Representative specifications of medium・big systems

| MODEL | Dia x Len | Temprature | Pressure |

|---|---|---|---|

| AIP8-20-5W | 8”/200mm–20”/500mm | 205F/96C-300F/150C | 5,000psi/34MPa |

| AIP12-24-5W | 12”/300mm–24”/600mm | 205F/96C-300F/150C | 5,000psi/34MPa |

| AIP20-30-2W | 20”/500mm–30”/760mm | 205F/96C-300F/150C | 2,000psi/14MPa |

| AIP30-48-2W | 30”/762mm–48”/1220mm” | 205F/96C-300F/150C | 5,000psi/34MPa |

Refer to the URL below in details.