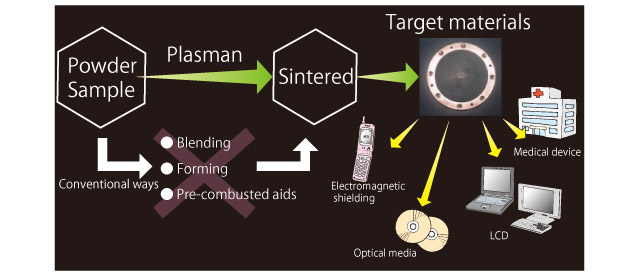

PLASMAN(PCS:Pulse-current sintering)

PLASMAN IS THE KEY TECHNOLOGY IN THE 21st CENTURY.

PLASMAN IS THE KEY TECHNOLOGY IN THE 21st CENTURY.

PLASMAN is a conventional energization heat processing method that uses a unique and epoch-making patented technology.

|

|

|

| Industry Size: CSP-V | Mini Size: CSP-II | PLASMAN KIT: CSP-KIT |

|

|

| PLASMAN MINI | PLASMAN KIT automatic |

Features

- The adoption of a hot wall prevents horizontal heat diffusion and homogenizes the temperature and density of the material.

- The use of a laminated graphite prevents vertical heat diffusion and homogenizes the temperature and density of the material.

- A wide variety of raw materials such as metals, ceramics, and resins can be heat-processed (sintered, joined, and melted).

- Various target materials/FGM: Ideal for functionally graded materials.

- NAVIWAVE SYSTEM is a real-time quality control system that measures, records, and controls products.

- The power supply uses the inverter direct pulse method and can be added in parallel.

- Saves total input energy.

- The heat processing time can be reduced and the development window/manufacturing cycle can be shortened.

- Reduces total CO2 emissions.

- Improves your work process environment.

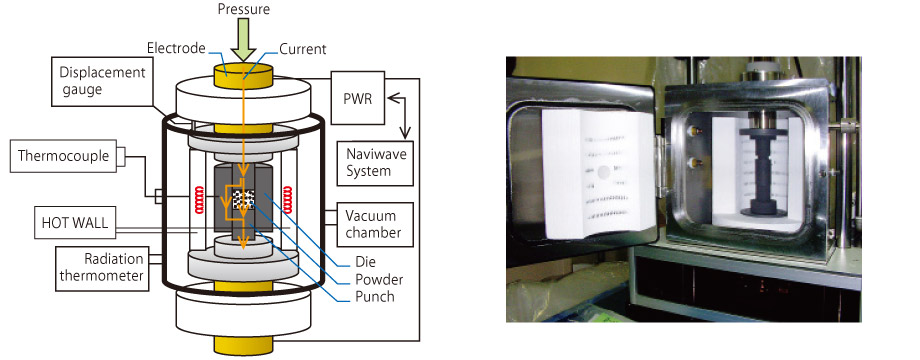

Principle

PLASMAN is an advanced thermal processing system, “Spark Plasma Sintering” utilizing direct electric conduction and pressurized energy. With innovative patented technologies: HOT WALL and LAMINATED GRAPHITE FORM, PLASMAN achieved the enhanced homogenization of composite materials with considerably less energy consumption, process time, and CO2 emissions than conventional sintering methods.

- HOT WALL

HOT WALL is a patented technology that employs metal heater under 1000℃ and carbon heater over 1200℃. This allows less heat dissipation than traditional sintering ways, and achieves the enhanced homogenization of composite materials.

【System Image】

Specifications

| Type | Industry | Small/Medium sintering | PLASMAN KIT | |||

|---|---|---|---|---|---|---|

| Model | CSP-V | CSP-Ⅱ | CSP-KIT | |||

| Press capacity | 60tons~ | 5 tons, 5~60 tons | 2tons | |||

| Press control | Hydraulic control | Servo control & Hydraulic control | Hydraulic control | |||

| Stroke | 50mm~150mm | 50mm~100mm | 20mm~50mm | |||

| Punch electrode | Water cooling: 250mm~ | Water cooling: 80mm~ | Water cooling: 50mm | |||

| PWR | Invertor Control Power Direct current power |

Invertor Control Power Direct current power・Pulse power supply・ Pole conversion pulse power supply |

Invertor Control Power Direct current power |

|||

| Max.Output | Over 3000A~ 18000A(6000A×3) |

3000A・1000A(500A×2)・1500A(500A×2) | 500A | 1000A (500A×2) |

||

| Atmosphere | Vacuum・Inactive gas・Atmosphere | |||||

| Vacuum level | ~0.1Pa | ~x0.1Pa | ~10Pa | |||

| Regular temp | 1000℃ | 1500℃ | 1000℃ | 1500℃ | 1200℃ | |

| Temp measurement |

Thermocouple | Thermocouple・ Radiation thermometer |

Thermocouple | Radiation thermometer |

Thermocouple | |

| Regular work size | ~Φ180(mm) | Φ20~φ50(mm) | Φ10~15(mm) | |||

| Hot wall | Metal heater | Carbon heater | Metal heater | Carbon heater | Metal heater | |

| Control panel | Temp・Automatic pressure control Current / Voltage / Pressure displacement / Vacuum level |

Temp・Automatic pressure control Current / Voltage / Pressure displacement / Vacuum level |

Temp・Automatic pressure control Electricity・Voltage |

|||

| Measurement・Record・ Operation |

Software: Naviwave Hardware: laptop PC Port: USB Connection Operation |

Software: Naviwave Hardware: laptop PC Port: USB Connection Operation |

Options available | |||