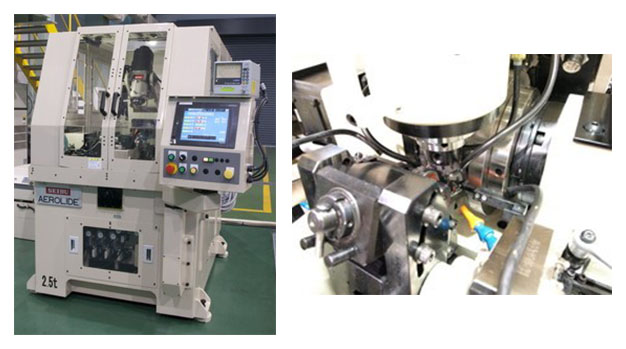

Previously it took long time to process a large ball only with a lot based production (with a batch of balls). However this machine enables to process a single large-size ball one by one in a short time with high.

Feature

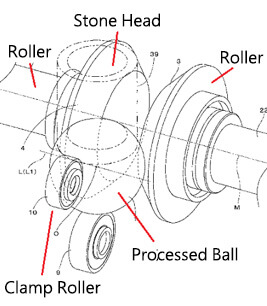

- A ball is rotated and continuously controlled by the drive rollers directly connected with the servomotors. During its rotation, as a circumferential speed between the right and left rollers are differentiated, rotational directions of the ball continuously change, and thus a cup stone contacts uniformly over the whole surface of the ball (Patent No. 5295307).

- A ball clamping system employs the air-driven clamp roller, and has a mechanism that rotations of the ball generated by difference in circumferential speed between the right and left rollers are not disturbed. This model is capable of machining large-size balls ranging from 0.D. 35 to 55 mm (φ20 〜 φ 76.2 mm applicable with special toolings). Set-up changes according to the ball sizes are easy.

- An air hydro-pressure system is adopted for a stone, and a stone head smoothly follows the configuration of the ball. Stable machining pressurization is obtained. Since a pressurization position is also retained by the automatic centripetal mechanism, re-alignment of the position is not required for replacement of the similar size balls.

- Each construction such as pressure roller, drive roller, operation panel, and overall cover are designed with greater emphasis on operability and maintenance.

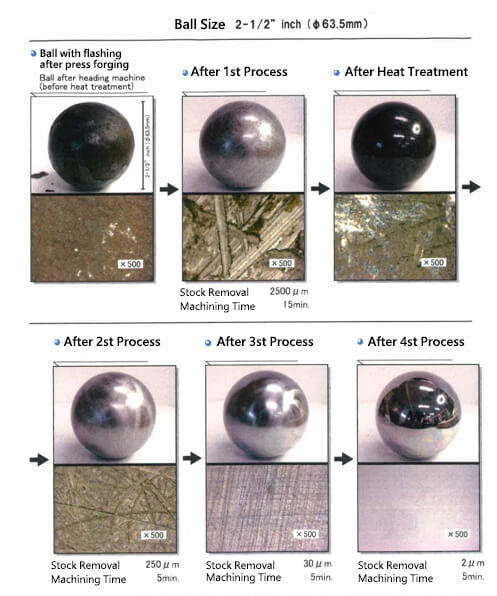

- This machine is capable of completing processes from rough to fine in three to five processes; one process takes about a few to 10 minutes. As this model is designed for machining a single ball, it will provide great cost performance in a small quantity with a variety of sizes.

- A special attachment to the lower support can easily get rid of flashings (belt-shaped projected parts) by switching a program of the roller rotation, which are generated during production of rough ceramic and steel balls.

Application

For ball bearings Precision machining of steel balls, ceramic balls and other material balls.

Processing example(SiN ceramics sphere)

Specification <example>

| Items | Contents | Remarks |

| 1) Work piece | Steel balls and ceramic balls for ball bearings, and balls of other materials |

|

| 2) Machining range | ||

| Basic | φ30 ~ 55 mm | |

| Special | Trial test machining and special toolings (with partial modification of the machine) are required for φ20 ~ 30 mm & φ55 ~ 76.2 mm・ |

special toolings is needed. |

| 3) Drive roller | ||

| Basic diameter | φ200 | |

| Taper angle | 90° | |

| Support angle | +7.5° | |

| Motor | 1.0 kW AC Servo motor | |

| Reduction gear | Reduction ratio 1/9 | |

| Revolution | ||

| Rated revolution | 220 rpm (Motor 2,000 rpm) | |

| Max. revolution | 330 rpm (Motor 3,000 rpm) | |

| 4) Support shoe | ||

| Support angle | -72.5° | |

| 5)Clamp roller | ||

| Diameter of clamping bearing | φ47 | |

| Clamp angle | +15° | |

| Clamp force | 280 kg (0.4 MPa時) | |

| Clamp stroke | 30 mm | |

| 6) Stone head | Rotating stone head with a cup stone by air hydraulic pressure | |

| Grindstone size | φ35×φ27×15L (Diameter of work piece is at φ47.625) | |

| Stone pressurization | Electropneumatic regulator control (rough/finish multi-step change-over) | |

| Stone pressurization force | 314kg (0.4 MPa時) | |

| Stone pressurization stroke | 50 mm | |

| Engage force | 314kg (0.4 MPa時) | |

| Engage stroke | 50 mm | |

| Motor | 3.5 kW AC servomotor Rated revolution 3,000 rpm, Max. revolution 4,500 rpm | |

| 7) Dimentions | (W)1,420×(D)2,215×(H)1,780 mm | |

| 8) Weight | 2,500 kg |