①Knife gate valve for powder Pinch gate valve MODEL: PG

Feature

- Air purge structure, a high sealing performance and durability.

- Powders stuck less.

- Very thin, small interplanar spacing, and does not require large space for installation.

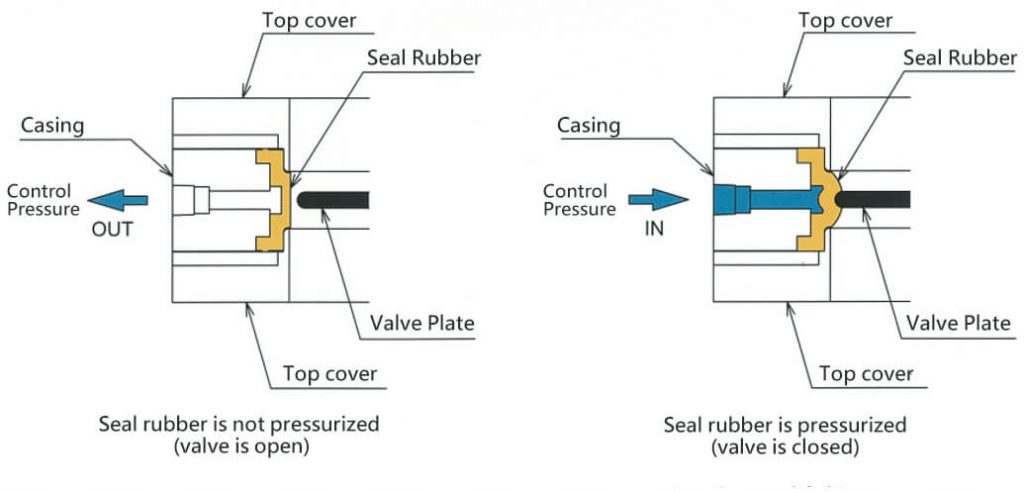

Working Principle

Application

Dry powder manufacturing plants for every industry

Specification

| Applicable flange |

Max. Pressure MPa |

Air Cylinder Operating Pressure Mpa |

Material | Sealcom material |

Heat resistance limit temperature |

|---|---|---|---|---|---|

| JIS5K | 0.19 (Seal rubber pressure 0.3) |

0.4 | Flouring Part SUS304 |

・NBR ・silicon |

・NBR:120℃ ・silicon:230℃ |

②Continuous supply / discharge device without biting MODEL: WD

Feature

- Can be supplied and discharged under negative pressure and pressure

- High sealing performance and durability due to the special spherical valve body

- No powder stuck.

- Arbitrary supply / discharge speed can be controlled.

- High maintainability due to large inspection port

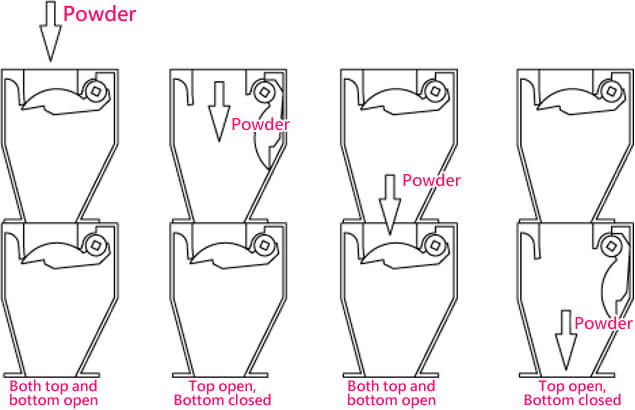

Principle

The upper damper opens and falls to the upper surface of the lower damper.

Close the upper damper and seal with the upper equipment.

The lower damper opens to supply and discharge powder and granules.

Close the lower damper and seal with the lower equipment.

Repeat the above operation to continuously supply and discharge.

Application

Dry powder in general, ceramics, resin, metal, glass, food, pharmaceuticals, pigments, powder paint, graphite, battery material, other organic, suitable powder, etc.

Specification

|

Compressed air consumption |

Emission capacity |

Connection diameter |

Body weight |

|

|---|---|---|---|---|

| NL/cyc | L/hr | kg | ||

| WD-130R | 40 | 900 | 125A | 75 |

| WD-200R | 45 | 2400 | 200A | 145 |

③Powder wiper Magical Knocker MODEL: MG

- Can be installed without welding

- A magnet valve allows automatic intermittent operation without an electricity supply.

- Directly collides the piston with the object and resulting in a big impact

- Strikes directly and high efficiency in removing powder.

- Able to adjust the collision strength.

- No refueling, non-seal type

- High durability

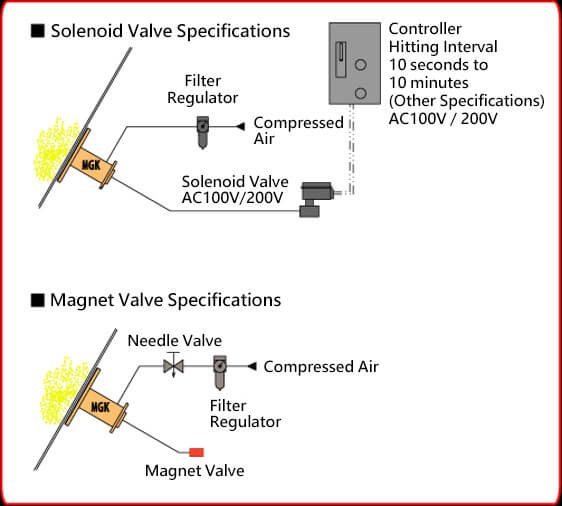

Working Principle

Application

Dry powder in general, ceramics, resin, metal, glass, food, pharmaceuticals, pigments, powder paint, graphite, battery material, other organic, suitable powder, etc.

Specification

| Working pressure range Mpa |

Strike power | Air consumption | Can be attached | |

|---|---|---|---|---|

| Mpa | N.m | L/Times | pipe | |

| MGK-30A | 0.1-0.2 | 0.57~1.13 | 0.02~0.03 | Minimum 100A |

| MGK-40 | 0.1-0.2 | 1.23~2.46 | 0.03~0.05 | Minimum 150A |

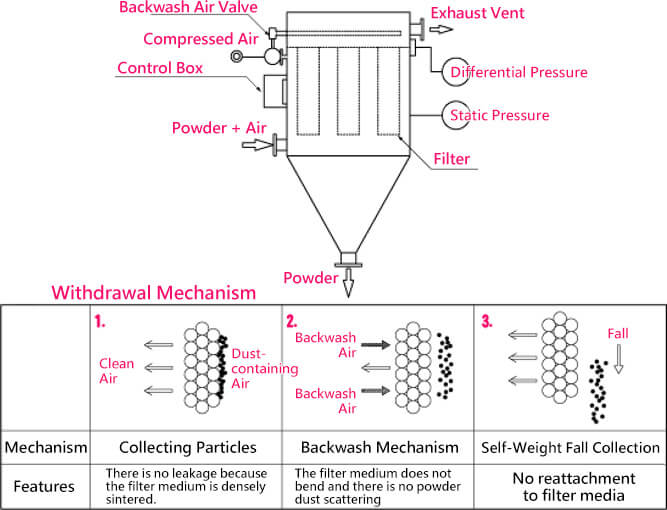

④ High-performance dust collector MODEL: PFR

Different elements used, great effects.

- Maintains stable collection performance because of surface filtration

- 99.999% dust collection

- No contamination to collected powder and can be washed

- High durability of the element

- Does not require large space and cost-effective

|

|

|

【Element】 |

【Equipped to a dust collector】 |

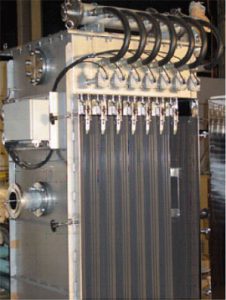

Working Principle

Application

Dry powder in general, ceramics, resin, metal, glass, food, pharmaceuticals, pigments, powder paint, graphite, battery material, other organic, suitable powder, etc.

Specification

| Filtration

area |

Compressed air

consumption |

Intake

diameter |

Exhaust

diameter |

|

|---|---|---|---|---|

| m3 | L/min | |||

| PFR-2A | 2 | 30 | 30A | 40A |

| PFR-200A | 200 | 212 | 300A | 300A |

*Various sizes and specifications available. Please feel free to contact.

⑤ Body cleaning solution-Powder cleaning solution Pneumatic Zero AL / AC

Principle

- Strong acid and alkali removes dirt quickly and shortens the time of detergency.

- No abrasives, cleaning without a scratch.

- Strong acid, strong alkali secures safeties.

① Disperse up to primary particles in a dispersion zone that utilizes the shearing force of a high-speed swirling flow. Dispersion power was improved by applying pressure air directly to the raw material.

② A strong classification zone is formed by the high-speed swirling centrifugal force generated by compressed air.

③ The structure that suppresses the turbulence of the central vortex prevents coarse particles from jumping in, and after classification, quickly discharges without staying in the device.

Application

Nickel, barium titanate, ceramics, resin, metal, glass, pharmaceuticals, pigments, paints, graphite, toner, powder paints, other organic and inorganic powders in general

Specification

| Product

name |

Pneumatic・Zero AL | Pneumatic・Zero AC |

|---|---|---|

|

||

| Liquid | Alkali | Acid |

| Component | Soda metasilicate, etc. | Hydrogen chloride

aqueous solution, etc. |

| Application | Powder, grease and oil stains | Mainly metallic

powder stains, scale |

| Quantity | 20L | 19L |

|

Non-conforming

material |

None | Aluminum, galvanized

material |