Feature

- Grinding by causing the particles to collide with the collision plate with the theoretical flow rate Mach 2 or more.

- It is also possible to crush a high hardness raw material which was conventionally impossible to crush.

- Coarse powder and fine powder are separated by a high performance classifier, and the coarse powder is again pulverized in the pulverization section to perform continuous classify treatment up to a predetermined particle size.

- SPK will be 1.4 to 2 times the production capacity of the same type CPY.

- There are no moving parts, so maintenance and inspection are easy.

- Low melting point, thermal sensitive material can be crushed by circulating cooling structure.

- There is no contamination with ceramic specifications ★.

(★: Optional specification)

Principle

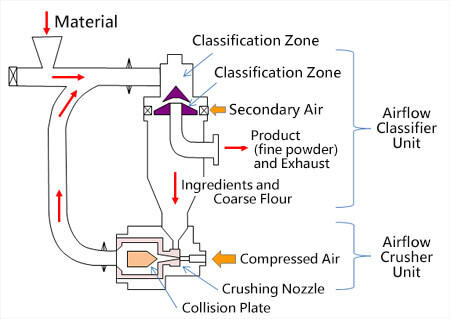

This collision plate type supersonic jet pulverizer is integrated with a high accuracy air classifier, and pulverization and classification are repeatedly performed. The raw material supplied to the aircraft is sucked and accelerated to a special milling nozzle capable of producing a supersonic air flow with a theoretical flow velocity of Mach 2.5 or more, and is subjected to high speed impact crushing with a collision plate installed in front of the nozzle.

The pulverized fine particles are classified by a highly accurate air flow classifier (DSF type or UFS type classifier) integrated in a regular manner, fine particles finer than the set classification point are discharged as products, and the coarse particles are discharged again It is introduced to the jet crusher, crushed, and repeatedly pulverized and classified to the target particle size.

Purpose

Crushing treatment of secondary battery materials, ceramics or hard materials, toner, pharmaceuticals, pigments, resins, metal powders, foods, silica, titanium oxide, graphite, alumina.

Specification

| Model | Compressed Air

Consumption |

Power

of Comp. |

Piping Dia | Weight |

|---|---|---|---|---|

| m3/min | kW | – | kg | |

| CPY(X)-2 + DSF-2 | 2.0 | 15 | 3.7 | 97 |

| CPY(X)-5 + DSF-5 | 5.0 | 37 | 18.5 | 171 |

| CPY(X)-10 + DSF-10 | 12.0 | 75 | 30.0 | 308 |

| CPY(X)-20 + DSF-20 | 20.0 | 125 | 55.0 | 809 |

| SPK-2 + DSF-2 | 2.1 | 15 | 3.7 | 24 |

| SPK-5 + DSF-5 | 5.0 | 37 | 18.5 | 70 |

| SPK-12 + DSF-10 | 12.0 | 75 | 30.0 | 125 |