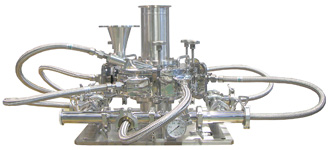

Pulverization and classification can proceed simultaneously, synergistic effect of classification by special mechanism design and improvement of grinding efficiency can be obtained.

Features

- The fine classification effect of the grinding zone gives the fine powder with a narrow particle size distribution of several tens of microns from the nano level.

- Coarse powder returns to the interior of the grinding nozzle and is reaccelerated, so the grinding effect is getting high.

- It is possible to crush low melting point, thermal sensitive substance.

- There is no contamination at the time of pulverization.

- Easy maintenance and inspection because there is no moving parts

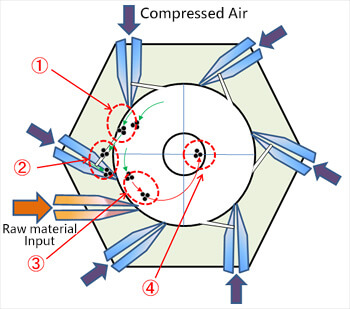

Principle

Continuously supply granules to a supersonic flow of Mach 2.5 or more will be crushed by impact between particles. At the same time, in the classification chamber provided in the pulverizer, the fine powder classified by the swirling force is recovered from the opening in the middle. The fine powder is collected by a cyclone or a dust collector, and the coarse powder is brought close to the wall side of the processing chamber by centrifugal force and accelerated again from the return hole. As a result, ultrafine particles having a sharp particle size distribution can be easily obtained with high efficiency.

① Coarse particles (raw material) are injected into the nozzle for raw material input and are centrifugal force due to compressed air flow

It swirls on the outside and is subjected to shock by collision of particles with each other and collision with a wall.

② Coarse particles are led to return holes.

③ Re-accelerated by six supersonic nozzles with compressed air, the inter-particle collision force increases.

④ Only finer particles are discharged from the center together with the air flow

① Coarse particles (raw material) are injected into the nozzle for raw material input and are centrifugal force due to compressed air flow

It swirls on the outside and is subjected to shock by collision of particles with each other and collision with a wall.

② Coarse particles are led to return holes.

③ Re-accelerated by six supersonic nozzles with compressed air, the inter-particle collision force increases.

④ Only finer particles are discharged from the center together with the air flow

Purpose

Crushing treatment of secondary battery materials, ceramics or hard materials, toner, pharmaceuticals, pigments, resins, metal powders, foods, silica, titanium oxide, graphite, alumina ,etc.

Specification

| Model | Compressed Air

Consumption |

Power of Comp. | Piping Dia | Weight |

|---|---|---|---|---|

| m3/min | kW | – | kg | |

| PJM-80SP | 0.5 | 5.5 | 20A | 11 |

| PJM-200SP | 2.8 | 22 | 80A | 58 |

| PJM-380SP | 7.0 | 55 | 125A | 140 |

| PJM-510SP | 12.5 | 125 | 150A | 230 |